TORLOPP GMBH

Glossary Machining

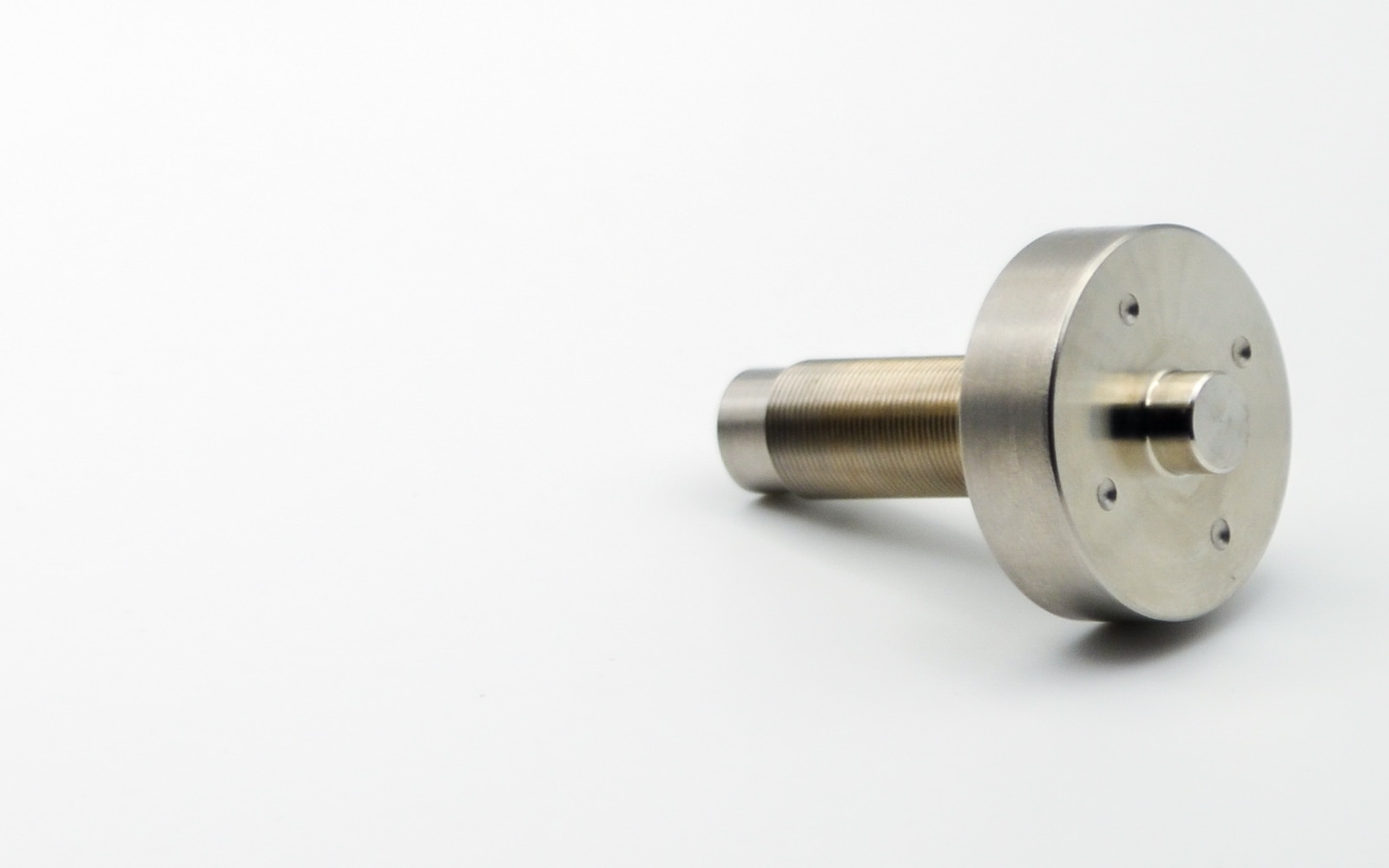

Machining is a process in which a workpiece is shaped or machined using a tool to improve its dimensions, surface quality, shape and accuracy.

There are various methods of machining, including turning, milling, drilling and grinding. Each of these methods has its own advantages and applications.

When turning the workpiece is held in a rotating motion while the tool cuts off material. Turning is often used to manufacture cylindrical parts such as shafts and axles.

When milling, the workpiece is held while the tool rotates or moves to cut the material. Milling is often used to produce flat surfaces and complex shapes.

Drilling involves drilling a hole in the workpiece. Drills can be used in different sizes and shapes to create holes with different diameters and depths.

When sanding, the workpiece is rubbed with an abrasive to achieve a smooth and precise surface. Sanding is often used to polish or smooth surfaces.

Machining requires precise control of the tool path and the workpiece to ensure that the end product has the desired shape and accuracy. Modern CNC (Computer Numerical Control) machines enable automated control of the machining process, which increases production efficiency and accuracy.

Our expertise, your advantage

Do you have any questions? We provide competent and comprehensive advice. Take us at our word:

Industrial technology advice: +49 (0)48 21 – 89 79-0

Measurement technology advice: +49 (0)48 21 – 89 79-79

You can also send us an e-mail – info@torlopp-gmbh.de – or use the contact form.