TORLOPP GMBH

Our performance strengths

Production and delivery of:

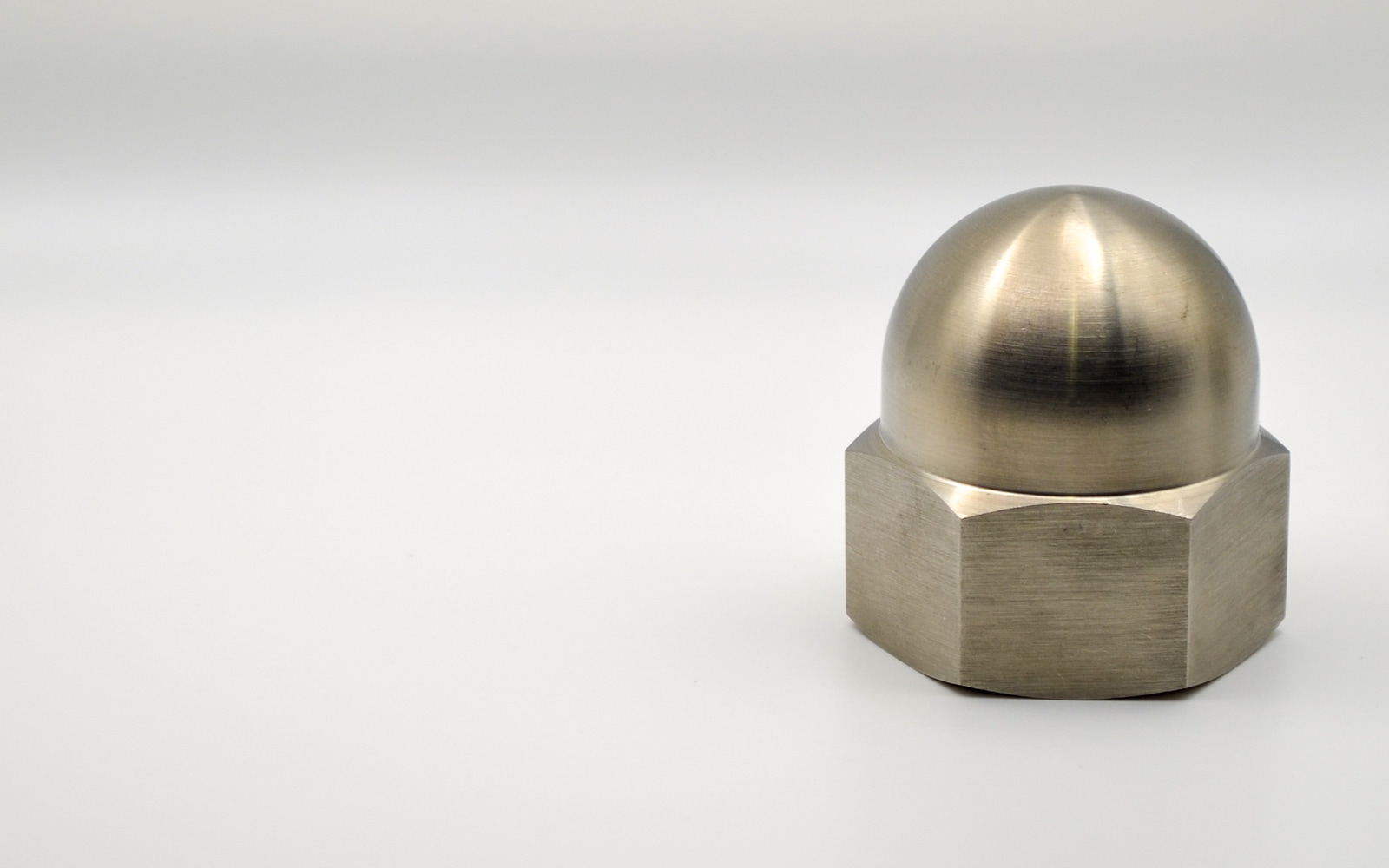

Precision turned parts and precision milled parts -> more…

Fasteners from M2 to M250 -> more…

Standard parts and special parts -> more…

Test gauges -> more…

Measuring service and test equipment monitoring service -> more…

Machinery includes CNC machining centers, CNC sliding headstock lathes, CNC short lathes, CNC bar lathes as well as conventional lathes and milling machines

Workpiece dimensions from 1 to 250 mm diameter from 1 to 1,500 mm length

Batch sizes from 1 to 1,000,000 pieces – prototypes, individual items, small series, large series

Materials almost all materials incl. special materials

Turning, milling and grinding production types from a single source

Additional machining operations Drilling, countersinking, threading, honing, lapping, eroding, etc.

Heat treatment Tempering, hardening, nitriding, annealing, etc.

Surface treatments Coating, electroplating, nickel plating, copper plating, galvanizing, phosphating, etc.

Monitoring service for measuring equipment and test equipment acc. DIN EN ISO 9000ff.

Our expertise, your advantage

Do you have any questions? We provide competent and comprehensive advice. Take us at our word:

Industrial technology advice: +49 (0)48 21 – 89 79-0

Measurement technology advice: +49 (0)48 21 – 89 79-79

You can also send us an e-mail – info@torlopp-gmbh.de – or use the contact form.